Rexsil is a company that specialises in quality production of silicone rubber products.

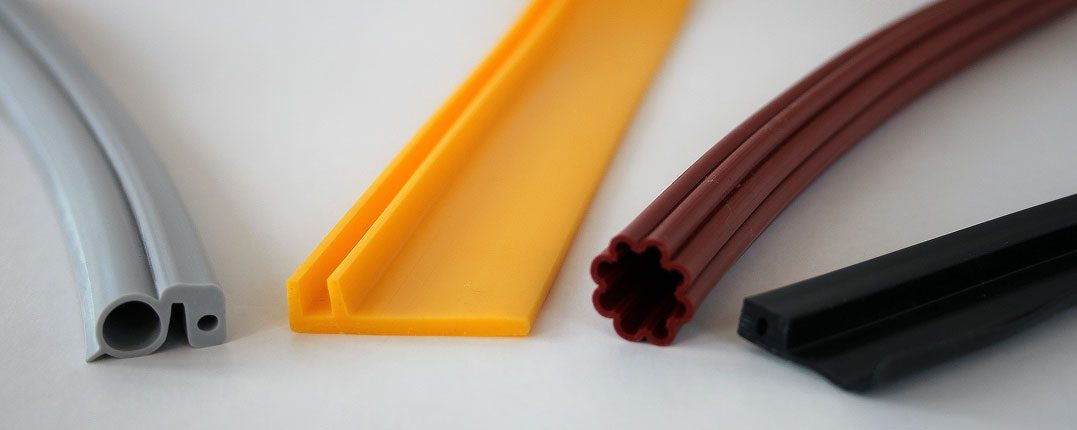

Rexsil specialises in manufacturing extruded silicone rubber products. We produce profiles, weather strip, gaskets, self-vulcanizing silicone rubber insulation tapes and tubes. We can also offer our customers injection moulded products. We are a small but experienced and knowledgeable company that has produced over 600 different profiles since our establishment in 1989. In addition, a large part of our production caters to sealing applications. In 2011, Rexsil became a part of Rego Silicones Group.

From the beginning, Rexsil had a production facility of 650 m2 (sq. m.). Due to demand, we expanded our facility to 1150 m2 (sq. m.) in 1997. Then in 2013, we expanded our facility for the second time to 1830 m2 (sq. m.). Rexsil is a manufacturer that is continuously growing to fulfil the needs of our customers. We have in-house mixing that helps us maintain quality standard and speeds up manufacturing and delivery process.

Our strength lies in our company size and know-how. We can assist our customers from start to finish. Our business philosophy is based on problem solving for our customers so flexibility and good service comes naturally. Producing high quality custom products on short lead times is a natural part of our business.